Zet@Master

The Zet@Master instrument is the highest-performance version of the Zet@ range, designed for defect detection and multi-sensor applications.

It allows multiple Eddy Current systems to be connected to a single device, and can be easily integrated into a production line.

The Zet@Master’s comprehensive I/O interface enables dialogue with various production line components.

It runs under Windows and is compatible with all CONTROLE MESURE SYSTEMES software.

With Zet@Master, all inspection results are displayed in real time, and an analysis report is produced for quality control follow-up.

Zet@Master meets the requirements of current European and international standards (ASTM, API, DIN, SEP, BS, ISO, ASME, ASNT…), calibration standards and complies with NF EN ISO 15548-1.

MAIN ADVANTAGES

- Stand-alone instrument with high performances, compact and easy to use

- Multi-channel and multi-frequency instrument for inspection at very high speed

- Compatible with all our software

- Real-time display of results, analysis report for quality inspection tracing

- Possibility to manage different controls and sorting delays with encoder or timer

- I/O interface to communicate with different production lines

- Analog interface and encoders

- Runs on Windows

- Products range

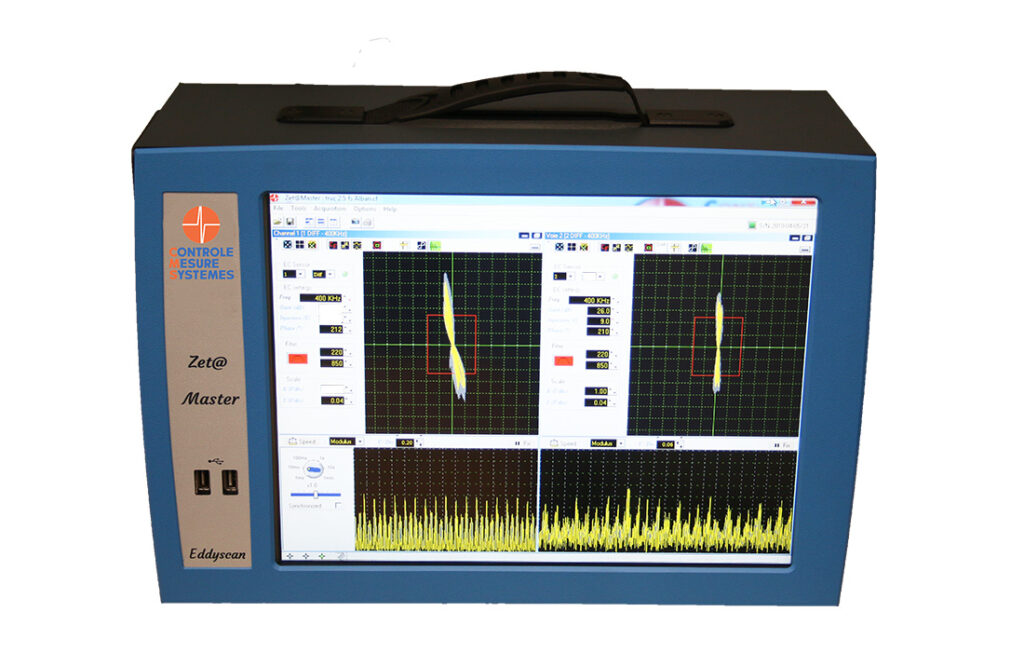

Standalone with touch screen

- Dimensions (inch): 10.4×16.1×6.3 (HxWxD)

- Dimensions (mm): 265X410X160 (HxWxD)

- Poids (kg): 8

- Power: 100-240 Vac – 50-60 Hz

- Number of channels: up to 32 channels

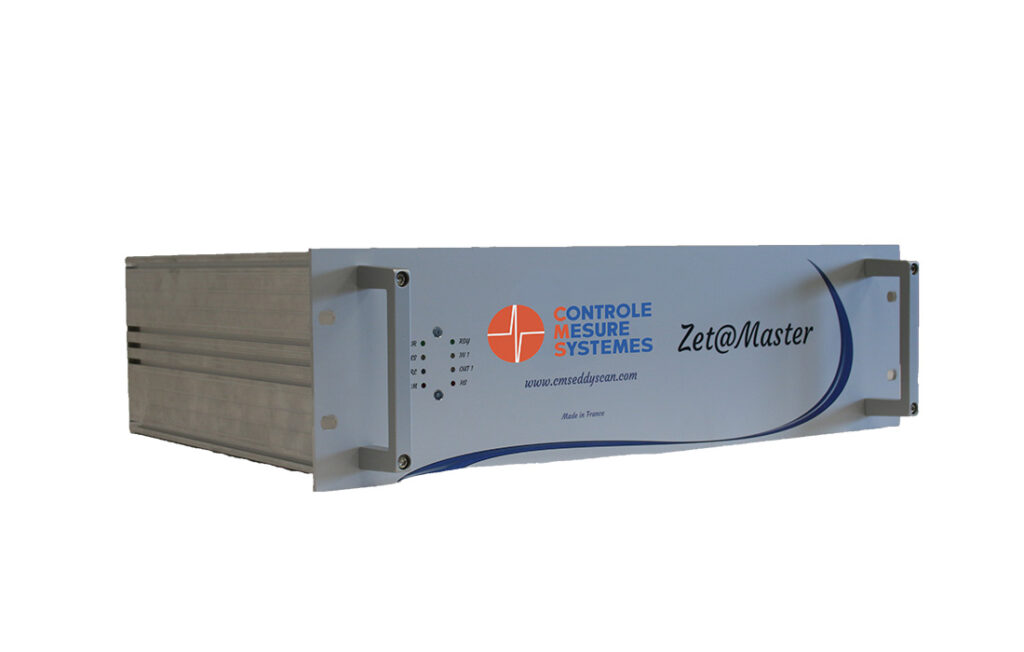

Rackable 3U

- Dimensions (inch): 5.2x19x13.5 (HxWxD)

- Dimensions (mm): 131X482X344 (HxWxD)

- Poids (kg): 5,5

- Power: 100-240 Vac – 50-60 Hz

- Number of channels: up to 32 channels

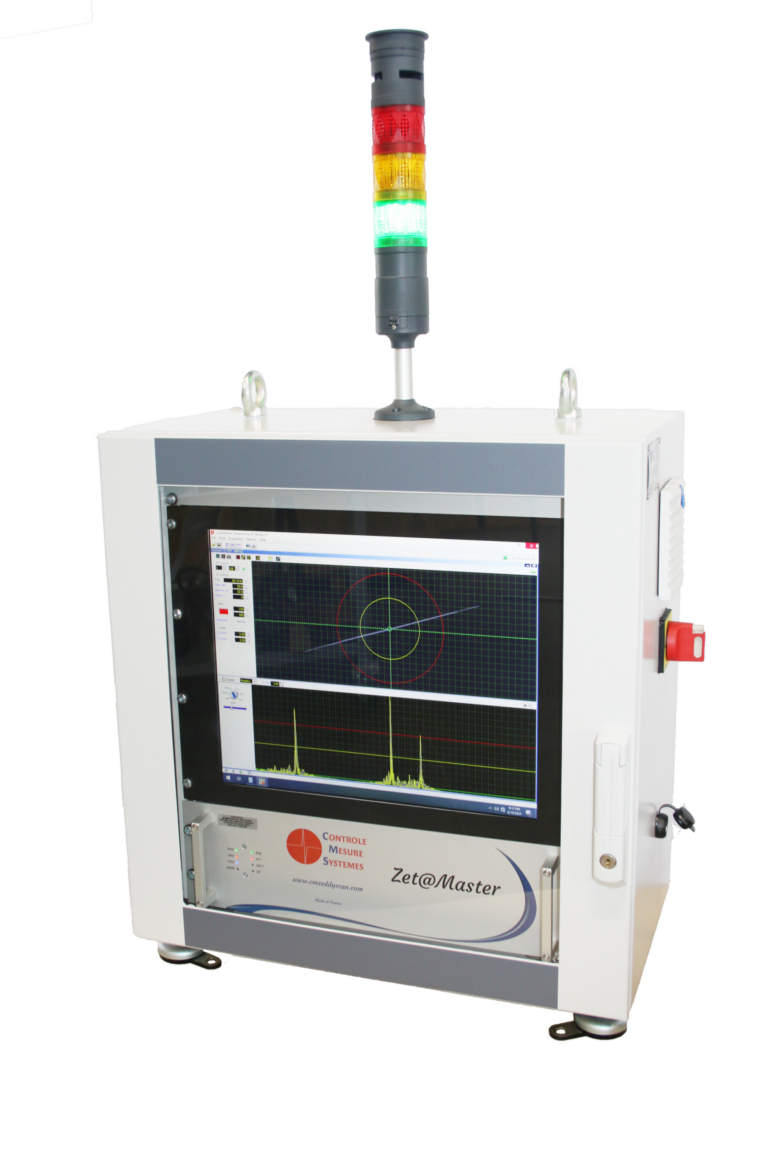

Zet@ instruments can be integrated in two ways:

Mini Cabinet

Free Standing Cabinet

- Operating principle

The instrument is controlled by configuration software, which defines the Eddy Current parameters for the application, such as measurement settings and alarm thresholds for defect detection.

Signal analysis is fully handled by the instrument’s electronics, providing real-time display of inspection results.

The device’s opto-isolated inputs and outputs enable quick and easy integration with the production line.

Other standards and/or specific software can be integrated into the instrument to meet user requirements (e.g., production software with inspection reports, signal recording for post-processing).

Customized software can also be developed specifically for your application.