Magnetizing Unit

Coupled with an encircling coil, the magnetizing unit enables the detection of punctual and transverse defects on the surface or sub-surface of ferromagnetic products at unlimited inspection speed.

Magnetic saturation and encircling coil control exclude the influence of permeability fluctuations.

Generally installed directly on the production line, this system can inspect bars, tubes, round, square or hexagonal wires using interchangeable encircling coils.

An opening version of the magnetizing unit is available: it can be positioned off-line or on-line to inspect continuous products (wire, bar) without having to cut them (Ø 5 to 55 mm).

All Zet@Micro, Zet@Premium and Zet@Master Eddy Current instruments can be combined with this system, in standard touchscreen or rackable versions.

This system complies with international standards such as ASTM, API, BS, AF, DIN, EN, SEP and others.

MAIN ADVANTAGES

- Quick & easy change of inserts and guide sleeves

- No-contact with the product

- High sensitivity of defects detection

- Unlimited control speed

- Can be combined with a wide range of CMS accessories

- Low maintenance

- Robust construction

- Adjustable magnetic field

- High-performance CMS software

- Products range

| Mag Monobloc | Mag T1 | Mag T2 | Mag T2 sp | Mag T3 | Mag T4 | Mag T5 | Mag T6 |

| Ø range (inch) | 0.008 – 11/16 | 1/32 – 1.75 | 1/32 – 2 | 1/32 – 4 | 3/16 – 5.5 | 3/16 – 7 | 2 – 9 |

| Opening version | Mo T1 | Mo T2 |

| Ø range (inch) | 3/16 – 1 | 3/16 – 2 |

- Products range

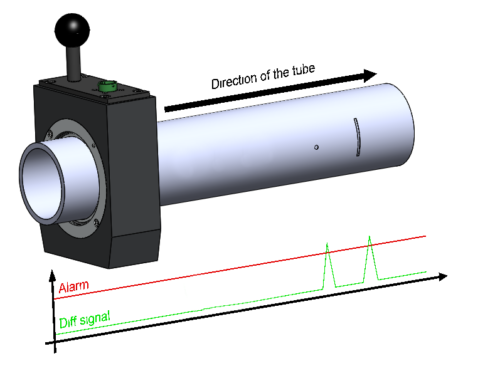

The product moves in translation inside the magnetizing unit. The Eddy Current encircling probe is located at its center.

The magnetizing unit magnetically saturates the material, enabling inspection by encircling coil. This technique can be used to inspect bars, tubes or wire of round, square or hexagonal cross-section. Several angular sectors can be inspected by separate coils. The presence of a point or cross fault varies the impedance of the coil.

Results are displayed directly on the instrument screen in a time base and/or impedance plane, with real-time alarm management. The addition of a downstream demagnetizing unit enables material to be desaturated after testing.