Rotating Head RotoUTscan

Installed directly on the production line, the RotoUTscan rotating head is dedicated to the high speed inspection of cylindrical products such as tubes, bars and wires. The aim is to detect internal and external defects of any orientations.

This system can be integrated into a mechanical bench with additional Eddy Current and/or Ultrasonic systems for complete product inspection.

The Ultrasonic instrument associated with this application is the MultiUTscan, available in a rack-mounted version for easy integration into control cabinet. CMS Ultrasonic software, Probus, allows the acquisition of all data, the display of the inspection in real-time and the creation of complete inspection reports.

The system is fully adaptable according to your products diameter.

RotoUTscan systems meet the requirements of current European and international standards (ASTM, API, DIN, SEP, BS, ISO, ASME, ASNT…), calibration standards and comply with NF EN ISO 22232-1.

MAIN ADVANTAGES

- Very high-speed inspection

- Minimum size of the detected defects: 25 µm of depth (0.001″)

- Dimensional measurement:

- Wall thickness measurement accuracy: 2 µm (0.00008″)

- ID, OD: 3 µm (0.0001″)

- Great modularity: fully adaptable to the client’s configuration

- Range of inspected products: from Ø 4 to 250 mm (5/32 to 10″)

- High-performance CMS software

- Products range

| Tube configuration | UTR-25 | UTR-40 | UTR-65 | UTR-90 | UTR-130 | UTR-180 | UTR-250 |

| Ø range (mm) | 4 – 25 | 6 – 40 | 12 – 65 | 18 – 90 | 28 – 130 | 42 – 180 | 70 – 250 |

| Ø range (inch) | 5/32 – 1 | 1/4 – 1.5 | 1/2 – 2.5 | 11/16 – 3.5 | 1.1 – 5.1 | 1.6 – 7 | 2.75 – 10 |

| Rotational speed (rpm) | 8000 | 6000 | 4000 | 3000 | 2000 | 1200 | 900 |

| Bar configuration | UTR-25 | UTR-40 | UTR-65 | UTR-90 |

| Ø range (mm) | 4 – 25 | 6 – 40 | 12 – 65 | 18 – 90 |

| Ø range (inch) | 2/32 – 1 | 1/4 – 1.5 | 1/2 – 2.5 | 11/16 – 3.5 |

| Rotational speed (rpm) | 6000 | 4000 | 3000 | 2000 |

- Operating Principle

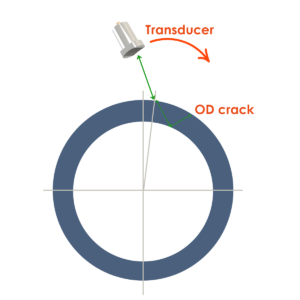

Ultrasonic transducers are rotated at very high speeds in immersion around the product to be inspected (e.g., tube, bar) as it moves linearly through the RotoUTscan rotating head. The combination of transducer rotation and product translation enables helical-pitch inspection.

The transducers are height-adjustable and can be precisely oriented along three axes for accurate positioning. Signal transmission and reception between the rotor and stator are contactless, ensuring seamless operation between the fixed and rotating parts.

The received signals are processed in real time and compared to the alarm thresholds defined during the calibration phase within the supervision system.