Rotating Systems

Robust, modular and evolutive, these systems rotate Eddy Current sensors. They are designed to detect internal and/or external defects. The sensors connected to this system are tailor-made for the product to be inspected. With high rotating speeds, these systems can be integrated directly into a production line.

The associated Eddy Current instruments are the Zet@Master and Zet@Premium, available in standard versions with touch screen or rackable.

MAIN ADVANTAGES

- Robust, modular and evolutive systems

- High rotating speeds

- Contactless sinal transmission

- Possibility to be integrated on-line (systems 5800 and 5810)

- High-performance CMS software

- Products range

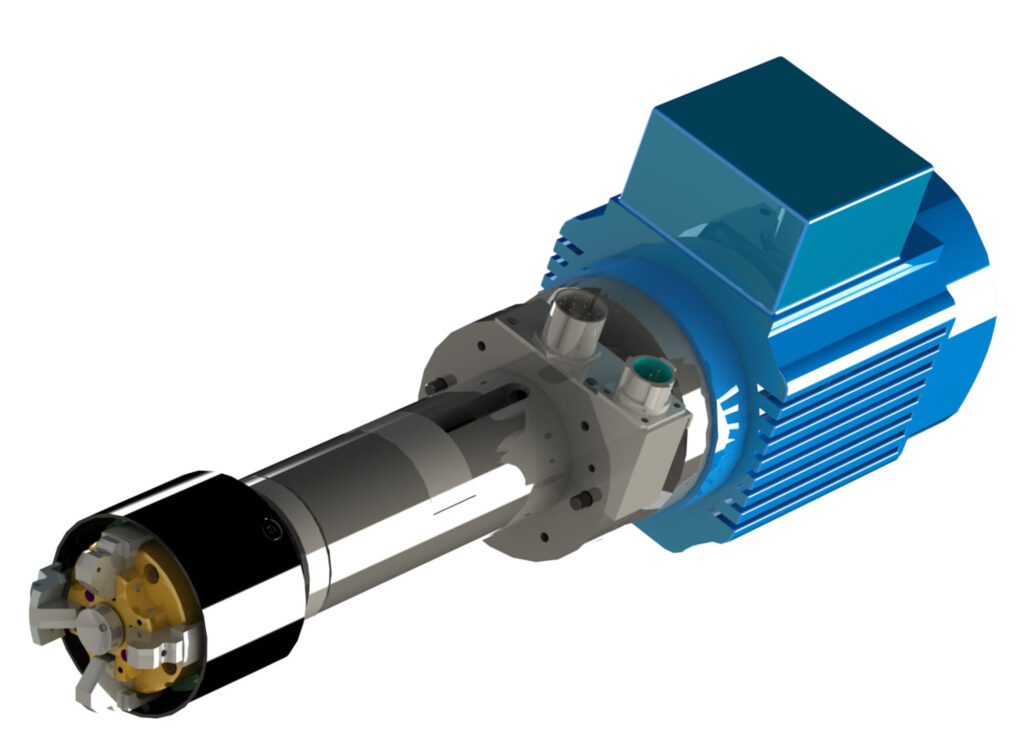

Rotating Gun 5500

- Rotating gun for checking small parts: checking bores, threads, tubes, etc

- Available in manual or industrial versions

Rotating Gun 5800

- 4 or 8 channels rotating system, controlled by Zet@Master or Zet@Premium CF equipment depending on the number of channels required

- It is specially designed for internal tube inspection and piston inspection (bore and combustion chamber)

- It can be linked to rotating discs for surface inspection of tubes or rectangular bars.

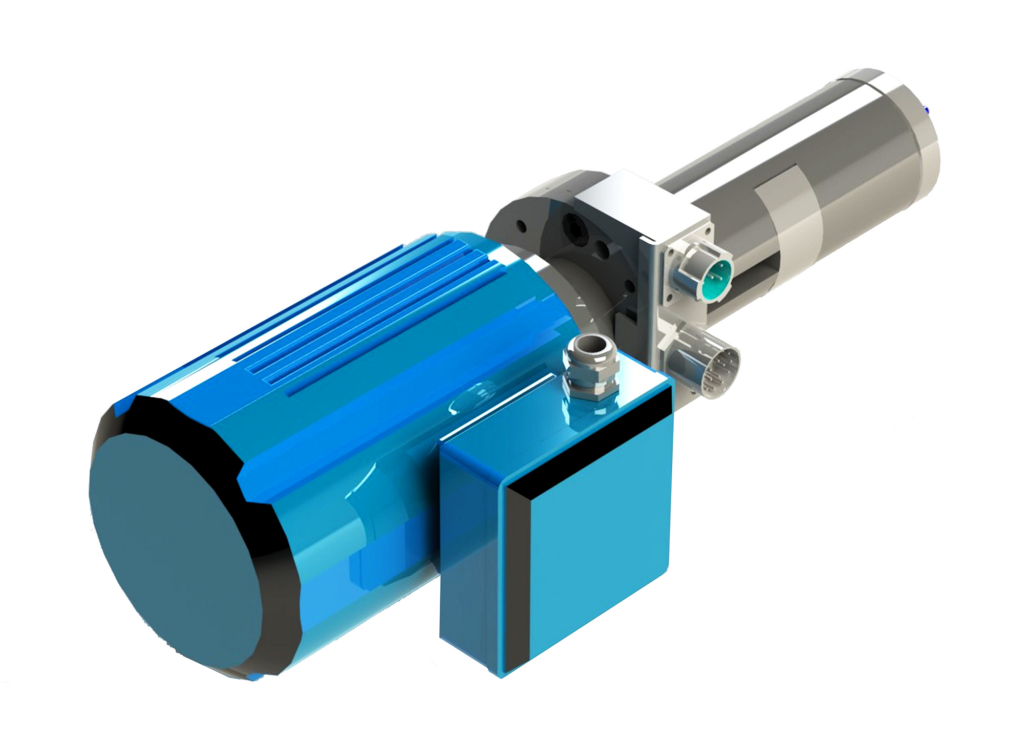

Rotating Gun ST 5810

- Rotating system for internal and/or external inspection of cylindrical parts or rails

- Products range

The rotating system rotates the Eddy Current probe on the surface or inside the product to be inspected. It excites the sensors and enables contactless transmission of signals between rotor and stator.