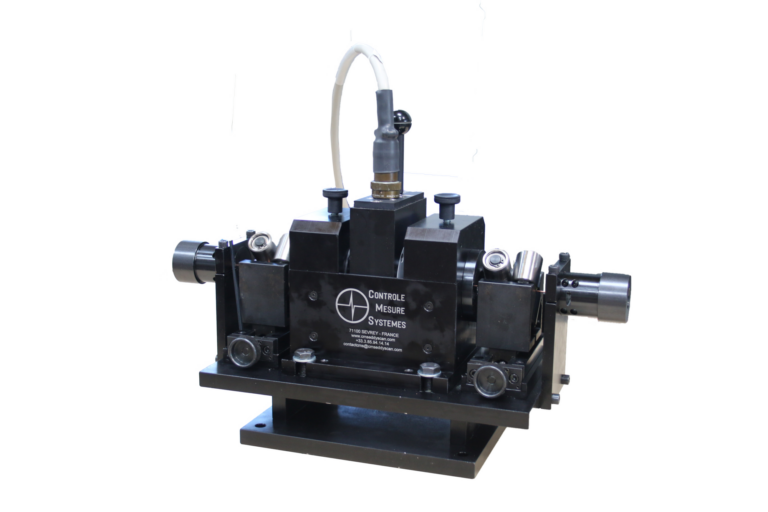

Encircling Coil and Support

The coil holders support and center the test coil on the product to be inspected. The complete system enables detection of surface and subsurface, short and transerve defects on non-magnetic products such as bars, tubes, round, square or hexagonal wires. Thanks to interchangeable encircling coils, a wide range of products with different profiles and diameters can be inspected.

The Eddy Current instruments associated with this system are the Zet@Premium and Zet@Micro, available in a standard touch-screen version or in a rackable version.

Two versions of coil supports are available, one for defect detection and the other for material sorting.

This system complies with international standards such as ASTM, API, BS, AF, DIN, EN, SEP and others.

MAIN ADVANTAGES

- Unlimited inspection speed

- Fast & easy change of guide sleeves, inserts and adaptors to match the product diameter

- Low maintenance

- Robust construction

- Non-contact with the product

- High-performance CMS software

- Can be combined with a wide range of CMS accessories

- Products Range

| Defects detection version | Support T1 | Support T2 | Support T3 | Support T4 | Support T5 | Support T6 |

| Ø range (mm) | 0.1 – 16 | up to 44 | up to 100 | up uo 135 | up to 180 | up to 230 |

| Ø range (inch) | 0.004 – 5-8 | up to 1.75 | up to 4 | up to 5.3 | up to 7 | up to 9 |

| Material Sorting Version | Tri T1 | Tri T2 | Tri T3 | Tri T4 |

| Ø range (mm) | 2-60 | up to 110 | up to 180 | up to 300 |

| Ø range (inch) | 0.08 – 2.3 | up to 4.3 | up to 7 | up to 12 |

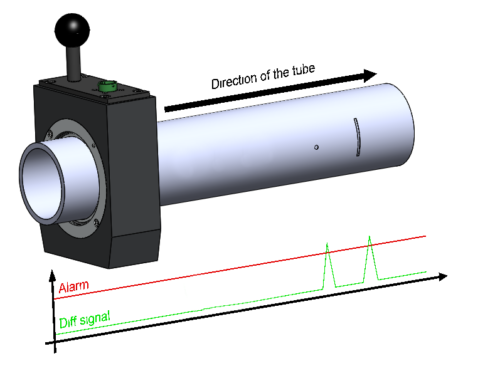

- OPERATING PRINCIPLE

The product passes in translation through the encircling coil. The presence of defects varies the impedance of the coil. Results are displayed directly on the instrument’s screen in a time base and/or in the impedance plane, with real-time alarm management.