Probus Supervision

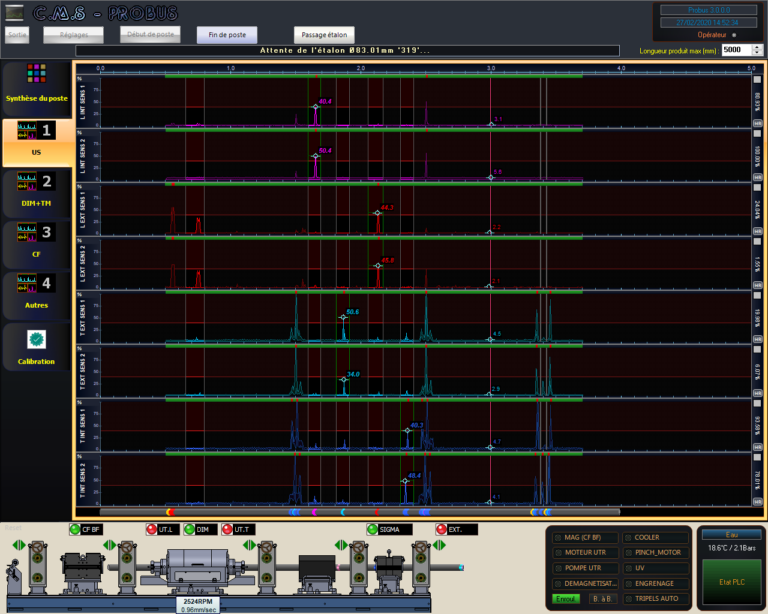

This software is used in applications requiring signal recording, in particular for controlling tubes, bars and wires on production lines.

Its purpose is to :

- Collect measurements from the various elements of Non-Destructive Testing by Eddy Current and Ultrasonic methods

- Display and analyze signals in real time

- Provide sorting sanctions

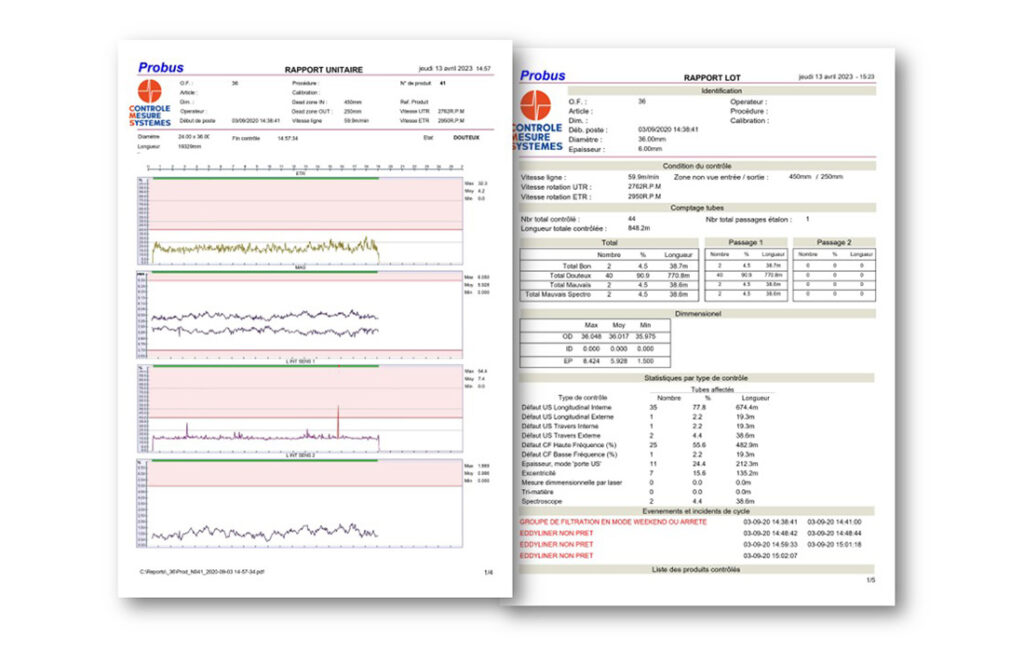

- Produce inspection reports

The Probus software is the decision-making element of the control bench. It centralizes all the line’s sensor data and is capable of controlling actuators. The software communicates directly with the control bench’s automation system, acting as its Human Machine Interface (HMI).

The main aim of Probus software is to ensure production traceability, with the creation of an inspection report for each product or batch at the end of the inspection. These reports can be presented as proof of inspection by quality departments and customers.

Probus Supervision is integrated into a separate screen on Zet@ and MultiUTscan instruments.

A network connection is possible from the interface for remote assistance.

MAIN ADVANTAGES

- Handles Eddy Current systems for the detection of surface defects

- Customizable configuration: management of several NDT elements

- Inspection reports by product and/or batch displaying the signals of every channels and listing the detected defects with their locations

- Network connection for remorte assistance

- Allows to meet the requirement of international standards (ASTM, API, DIN, SEP…)

- Allows a fully automated control with the supervision of all parts of every production line element and interfacing with a factory L3