Home | OUR INSPECTION METHODS – ULTRASONIC

Home | OUR INSPECTION METHODS – ULTRASONIC

Ultrasonics are widely used in Non-Destructive Testing (NDT) for the precise detection of internal and external defects, as well as for performing dimensional measurements in solid materials.

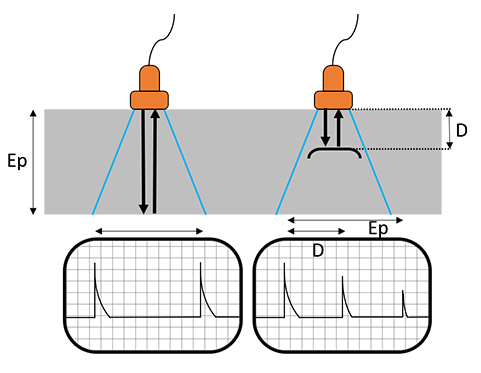

The principle is simple: an Ultrasonic wave is emitted by a sensor and propagates through the material being inspected. When the wave encounters a different medium (such as air), it reflects back to its point of origin. The analysis of the reflected wave provides information about the nature and characteristics of the detected defect.

To ensure effective propagation of Ultrasonic waves, a coupling medium (such as gel or water) is often applied between the probe and the material being inspected.

Examples of inspections with our Ultrasonic systems:

Detect defects with very high sensitivity: internal, transverse, longitudinal, oblique, holes and cracks

Weld inspection of tube

Perform dimensional measurements (thickness, ovality, eccentricity, internal and external diameter)

Precise inspection of very thick parts

Perform thickness measurement

All our Ultrasonic systems meet the requirements of current European and international standards (ASTM, API, DIN, SEP, BS, ISO, ASME, ASNT…), calibration standards and comply with EN 12668-1 and EN 22232-1.

| MultiUTscan: MultiUTscan is a powerful, high-precision, multi-frequency, multi-channel Ultrasonic inspection instrument. It performs defect detection, dimensional measurement (ID, OD) and thickness measurement. + technical information |  |

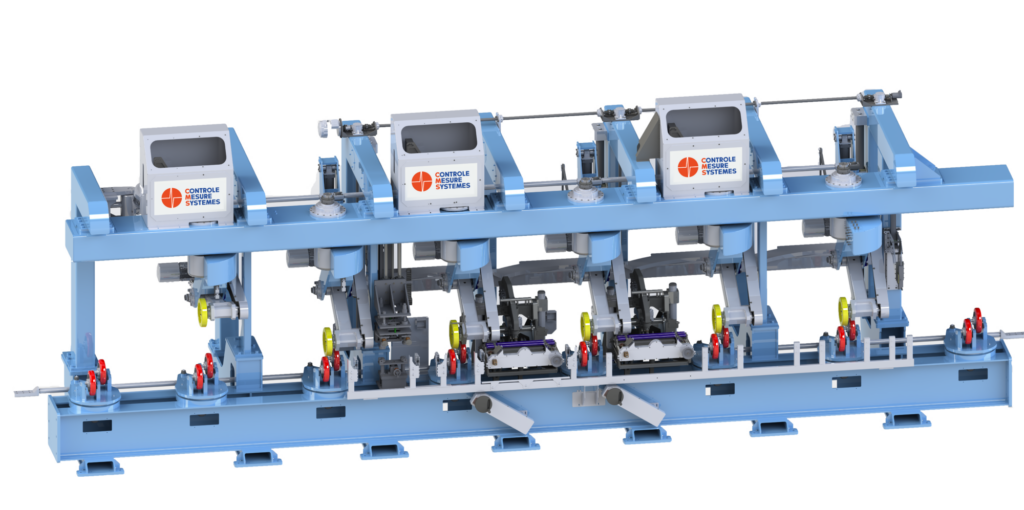

Rotating Head RotoUTscan: Dedicated to the detection of internal and external defects of any orientations on tubes, bars and wires, and performs dimensional measurements (ID, OD, wall thickness). |  |

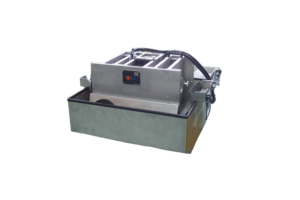

Immersion tank: The Ultrasonic Immersion tank provides scanning inspections carried out with conventional Ultrasonic or Phased Array electronics. |  |

UT Line: The Phased Array Ultrasonic inspection system detects internal and external defects on bars and billets at very high speed. |  |

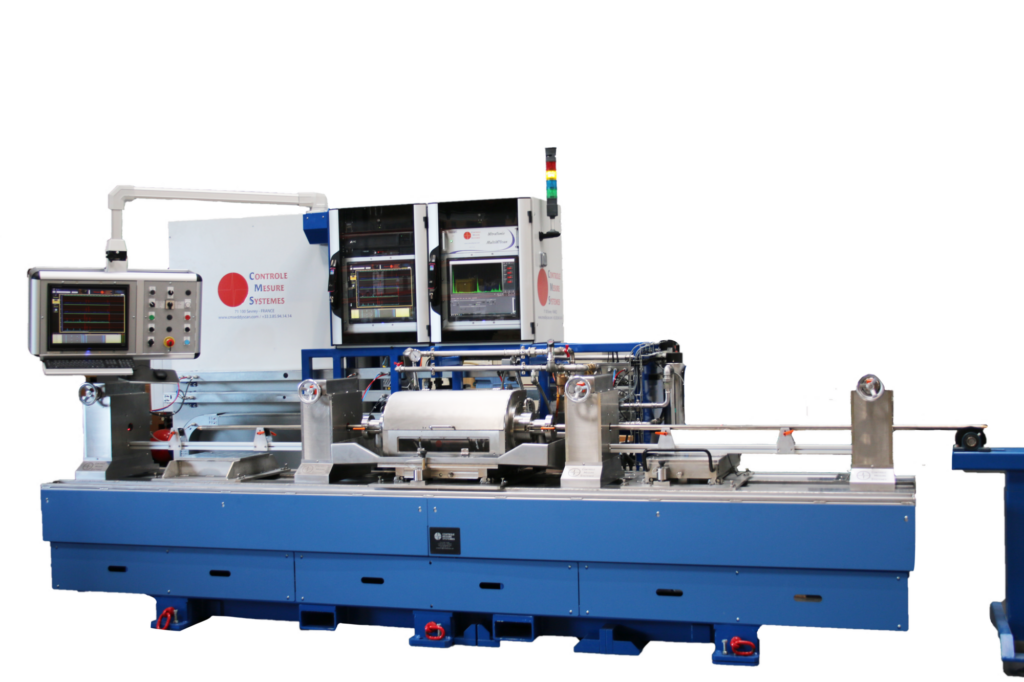

Ultrasonic testing of large-diameter tubes and bars: These kind of systems allow to offer an effective control solution for large-diameter tubes and bars. Two solutions are available: with gantry or with inspection bench. |  |

All our software is designed and developed in-house by our teams of electronics engineers. They are fully customizable and adaptable to your needs.

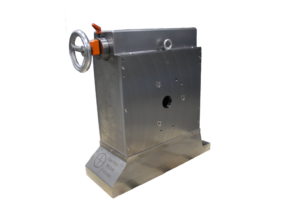

Mechanical control benches : For each application, a test bench may be required to support the various systems and thus ensure inspection under the best possible conditions. |  |

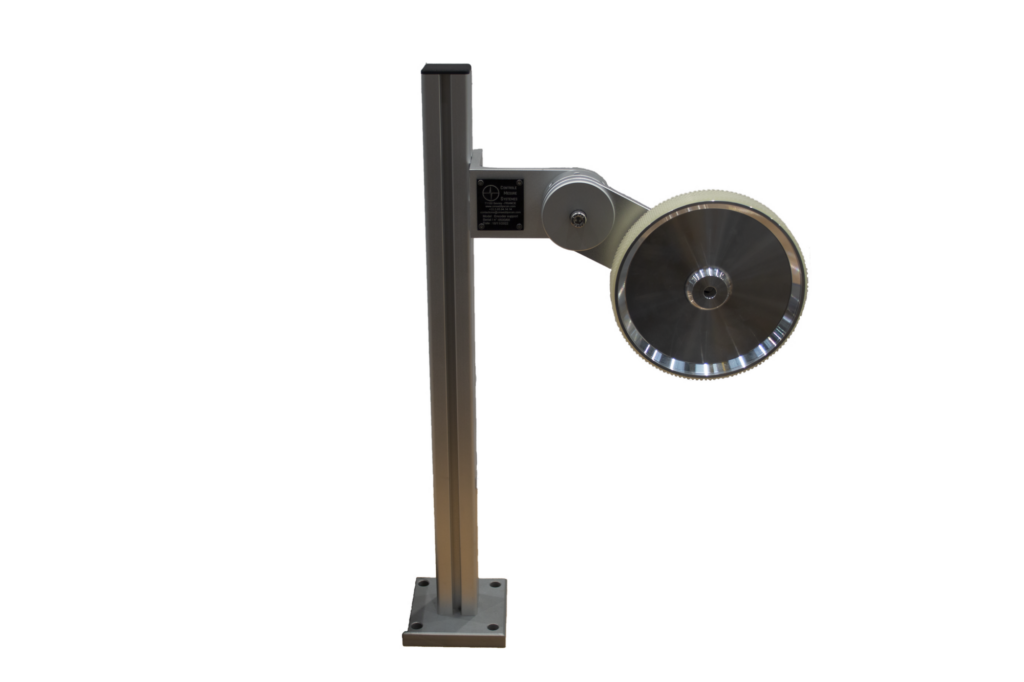

Centering systems : They enable precise product guidance. |  |

Other accessories : Discover the many other accessories CMS has to offer. |  |

| Engineering : Our team is made up of complementary technical profiles: a mechanical design office, an electronics design office and a team of specialized technicians who design and build all our turnkey NDT systems. |

Installation : Our technical team installs, checks and calibrates instruments and systems on site or at our premises, as requested by our customers. A calibration certificate is then issued. |

Training : We can offer you high-quality training to help you become more efficient and effective in using our control systems. |

Rental : We offer Non-Destructive Testing equipment for rental. This option can be very effective and economical when inspecting small production runs or during a period of equipment breakdown. |

Support : On-site or remote support, in real time, enables our engineers to offer our customers fast, high-quality technical service. |

After-sales service : CMS instruments, systems, probes and sensors can be repaired after expert, costing and agreement. Please contact us for further information. |

Some examples of our Ultrasonic applications installed at our customers’ site directly on the production line or on off-line inspection station:

Detection of internal and external defects on circular products (wires, tubes and bars) with RotoUTscan rotating head

Dimensional measurement (ID, OD, wall thickness) with RotoUTdim rotating head

Inspection of rotating parts with an Ultrasonic immersion tank consisting of a turntable

Bars and billets inspection with Ultrasonic Phased Array transducers

Automated in-line weld inspection

Ultrasonic station dedicated to thickness measurement

Our applications allow the Non-Destructive Testing of many products :

Since 1988, CMS designs, manufactures and installs turnkey Ultrasonic systems

Start from an Ultrasonic product to build a 100% customized solution based on our experience and and to meet your specific needs

Production and design of all our Ultrasonic instruments and software on our own premises

Highly responsive in providing asssitance and information to our customers

A wide range of complementary Ultrasonic systems/accessories that can be combined to provide inspection of ferrous and non-ferrous products

The RotoUTscan range provides high-speed immersion inspection (2 m/s) for a diameter range from 4 to 450 mm, highly accurate dimensional measurements, very high signal defect repeatability (<1dB), PRF up to 20 kHz, non-contact signal transmission…

Inspection speed optimized to production constraints

Ultrasonic inspection results are displayed in real time, and traceability is ensured by our production software, which creates complete inspection reports

INNOVATION: Ability to combine Eddy Current and Ultrasonic inspection methods for 100% product inspection

Contact details Fr

CONTROLE MESURE SYSTEMES

6 rue des Loches

71100 Sevrey – France

Contact details USA

CONTROLE MESURE SYSTEMES INC.

175 Pearl Street

Brooklyn, NY 11201 – USA

This new workspace, costing around 2.2 million euros, will enable CONTROLE MESURE SYSTEMES to increase its production capacity, develop its business by conquering new markets, and thus reinforce its position as leader in the NON-DESTRUCTIVE CONTROLE sector.

FEDER contribution : 590,000 Euros

For further information : https://www.europe-bfc.eu

Ce nouvel espace de travail, représentant un coût d’environ 2.2 millions d’euros, permettra à CONTROLE MESURE SYSTEMES d’accroitre sa capacité de production, de développer son activité par la conquête de nouveaux marchés et ainsi renforcer sa place de leader sur le secteur du CONTROLE NON DESTRUCTIF.

Montant FEDER : 590 000 Euros

Pour en savoir + : https://www.europe-bfc.eu