UT Line

UT Line Phased Array Ultrasonic systems enable very high-speed inspection of bars and billets in translation.

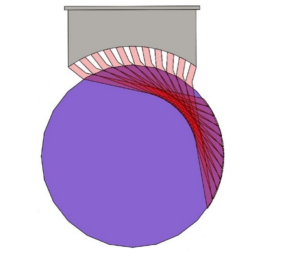

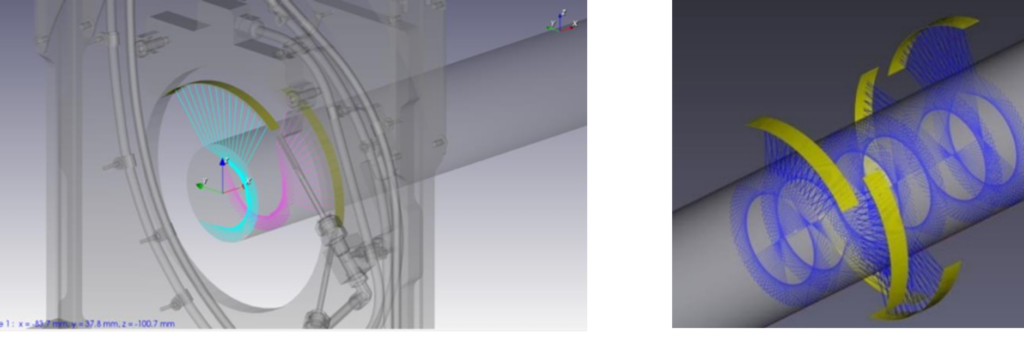

Several sectorial Ultrasonic probes are installed in cassettes, with an overlap between each one, enabling 360° inspection of the product.

The arrangement and type of sectorial probes enable detection of flat-bottomed holes (TFP), axial holes (SDH) and/or long defects (Common standard defect size: FBH 0.7 mm and SDH 0.3X10 mm).

Thanks to our experience, we can offer you a fully tailored system: PA transducers’ configuration is defined according to the standard defect size and the required inspection speed of the customer.

The system can be installed on the customer’s production line, or off-line with the addition of upstream and downstream bar conveyors, a sorting system and storage troughs.

The Ultrasonic instrument associated with this application is the MultiUTscan, available in a rack-mount version for easier integration in control cabinet.

This system meets the requirements of current European and international standards (ASTM, API, DIN, SEP, BS, ISO, ASME, ASNT…), calibration standards and comply with NF EN ISO 22232-1.

MAIN ADVANTAGES

- Possibility to generate longitudinal and transverse Ultrasonic waves

- Very high inspection speed (up to 2 m/s)

- Small amount of space needed on the line

- No bar handling

- Quick set up to switch between product diameters

- Floating cassettes to follow any imperfections of the product to inspect

- High-performance CMS software

- Products range

| UTline T1 | UTline T2 | UTline T3 | |

| Ø Range (mm) | 10 to 80 | 30 to 130 | 60 to 280 |

| Ø Range (inch) | 3/8 to 3.2 | 1.2 to 5.1 | 2.3 to 11 |

- Operating Principle

The bar passes through the inspection tank and the various probe blocks containing Phased Array transducers immersed in a constant volume of water.

Several automatic centering devices are also present inside the tank. The probe block has several degrees of freedom, enabling it to easily follow the bar and any imperfections.

The entire inspection zone is covered thanks to Phased Array technology, which enables electronic angular scanning of the beams without mechanical movements.

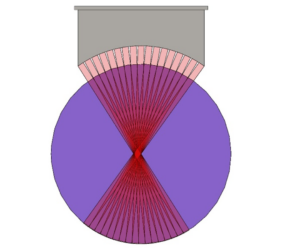

Examples of wave shooting for the detection of SDH and FBH

Examples of wave shooting for the detection of SDH and FBH