CMS offers you different types of Non-Destructive Testing, by Eddy Current and/or Ultrasonic, on forged parts to :

With inspection rates varying according to the defects sought, inspection can be carried out :

Our diversified product range enables us to offer you customized solutions for Non-Destructive Testing by Eddy Current and Ultrasonic, according to the geometry of the parts to be inspected, but also according to the type of defects sought, while complying with the standard of your choice.

Combined Eddy current and Ultrasonic testing is also available: the entire volumetric surface of the part is inspected to verify conformity.

This customization enables us to carry out a precision inspection and optimize inspection results.

All our Eddy Current and Ultrasonic systems meet the requirements of current European and international standards ASTM, API, DIN, SEP, BS, ISO, ASME, ASNT… calibration standards and comply with NF EN ISO 15548-1, NF EN ISO 15548-2, NF EN ISO 15548-3, NF EN ISO 22232-1.

Here a few examples of inspections carried out on forged parts:

Eddy Current inspection 3-axis robot

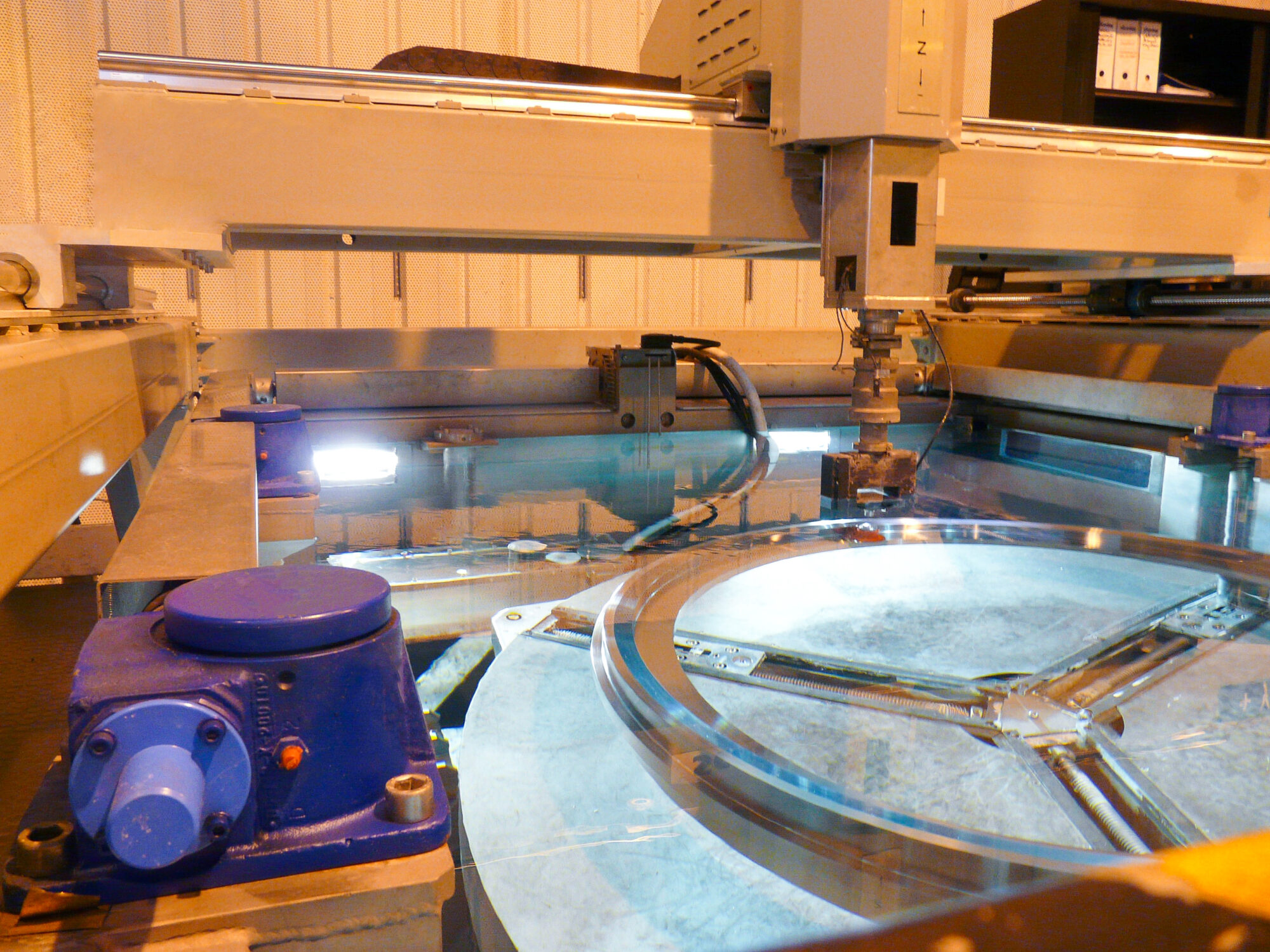

Ultrasonic immersion tank inspection

Over 36 years of experience in the design, manufacture and installation of Non-Destructive Testing systems for turned parts inspection

Start wiht and Eddy Current/Ultrasonic product and build a 100% customized solution absed on our experience and to meet your specific needs

Production and design of all Eddy Current & Ultrasonic probes, sensors and software on our own premises (mechanical and electronic design office, engineering, etc.)

Highly responsive in providing assistance and information to our customers

A wide range of complementary Eddy Current/Ultrasonic systems/accessories that can be combined for forged parts inspection

Eddy Current and Ultrasonic inspection results are displayed in real time and traceability is ensured by our production software which creates complete inspection reports

Inspection speed optimized to production constraints

INNOVATION: Ability to combine Eddy Current and Ultrasonic inspection methods for 100% product inspection

Contact details Fr

CONTROLE MESURE SYSTEMES

6 rue des Loches

71100 Sevrey – France

Contact details USA

CONTROLE MESURE SYSTEMES INC.

175 Pearl Street

Brooklyn, NY 11201 – USA

This new workspace, costing around 2.2 million euros, will enable CONTROLE MESURE SYSTEMES to increase its production capacity, develop its business by conquering new markets, and thus reinforce its position as leader in the NON-DESTRUCTIVE CONTROLE sector.

FEDER contribution : 590,000 Euros

For further information : https://www.europe-bfc.eu

Ce nouvel espace de travail, représentant un coût d’environ 2.2 millions d’euros, permettra à CONTROLE MESURE SYSTEMES d’accroitre sa capacité de production, de développer son activité par la conquête de nouveaux marchés et ainsi renforcer sa place de leader sur le secteur du CONTROLE NON DESTRUCTIF.

Montant FEDER : 590 000 Euros

Pour en savoir + : https://www.europe-bfc.eu