Manufactured from various metals such as steel, copper, aluminum, nickel and metallic, wires play a crucial role in numerous industrial sectors. Their versatility makes them essential for a wide range of applications.

In the aerospace and automotive industries, they are used in electrical harnesses, brake cables, and springs. In the electrical and electronics sectors, copper and aluminum wires are predominantly utilized for electrical cables, circuits, and windings.

The steel and metallurgical industries also heavily rely on metallic wires, particularly steel wires, which are commonly used in tire manufacturing, high-strength industrial cables, and even medical device production.

Wires and cables offer several key properties and advantages, including high conductivity, mechanical strength, flexibility, and resistance to corrosion and extreme temperatures—especially in the case of stainless steel and nickel. Their ability to be processed through rolling, drawing, or extrusion further enhances their appeal across various industries.

Given their critical role, the quality of metallic wires must be impeccable to meet the stringent requirements of industrial applications.

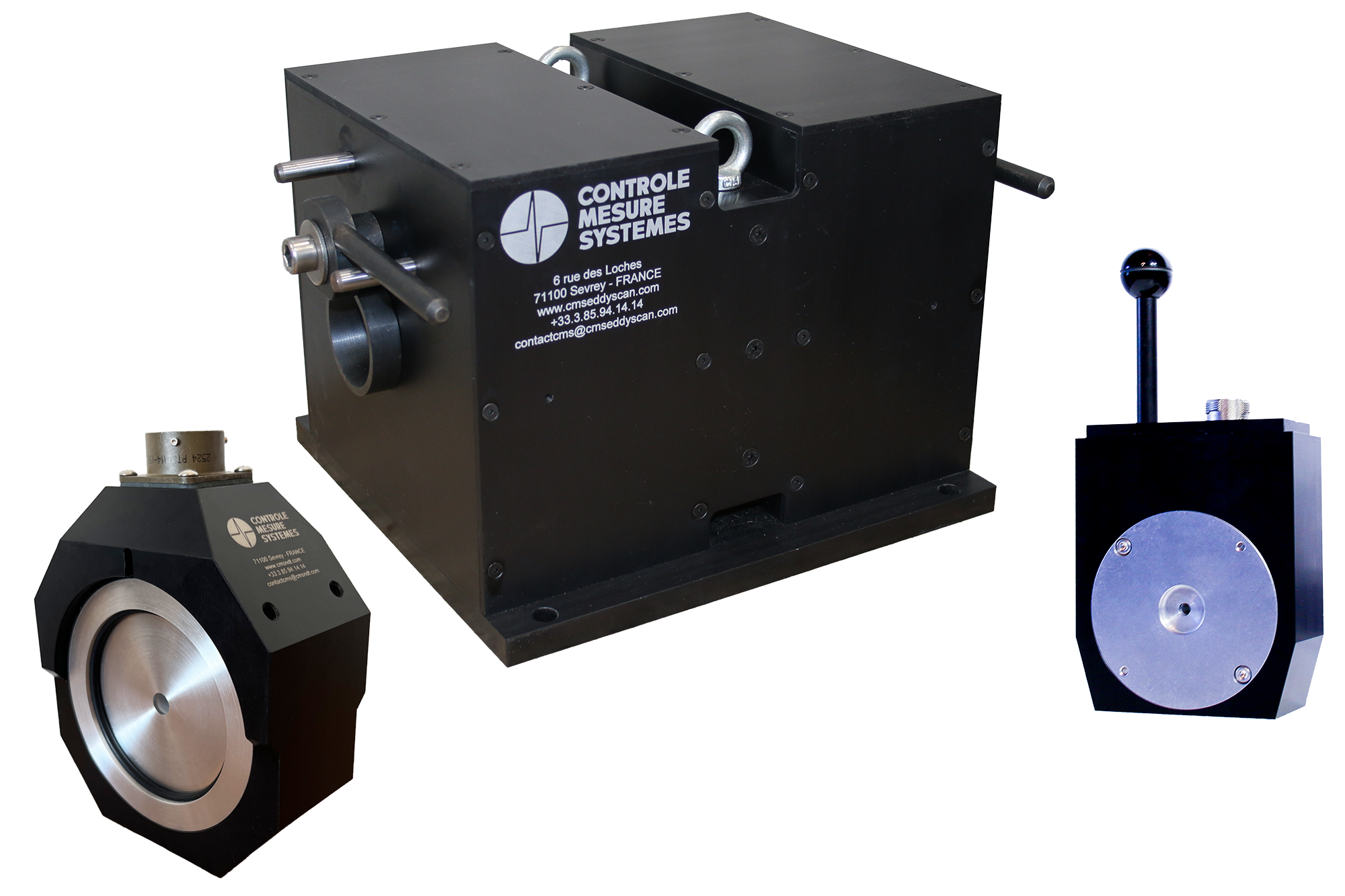

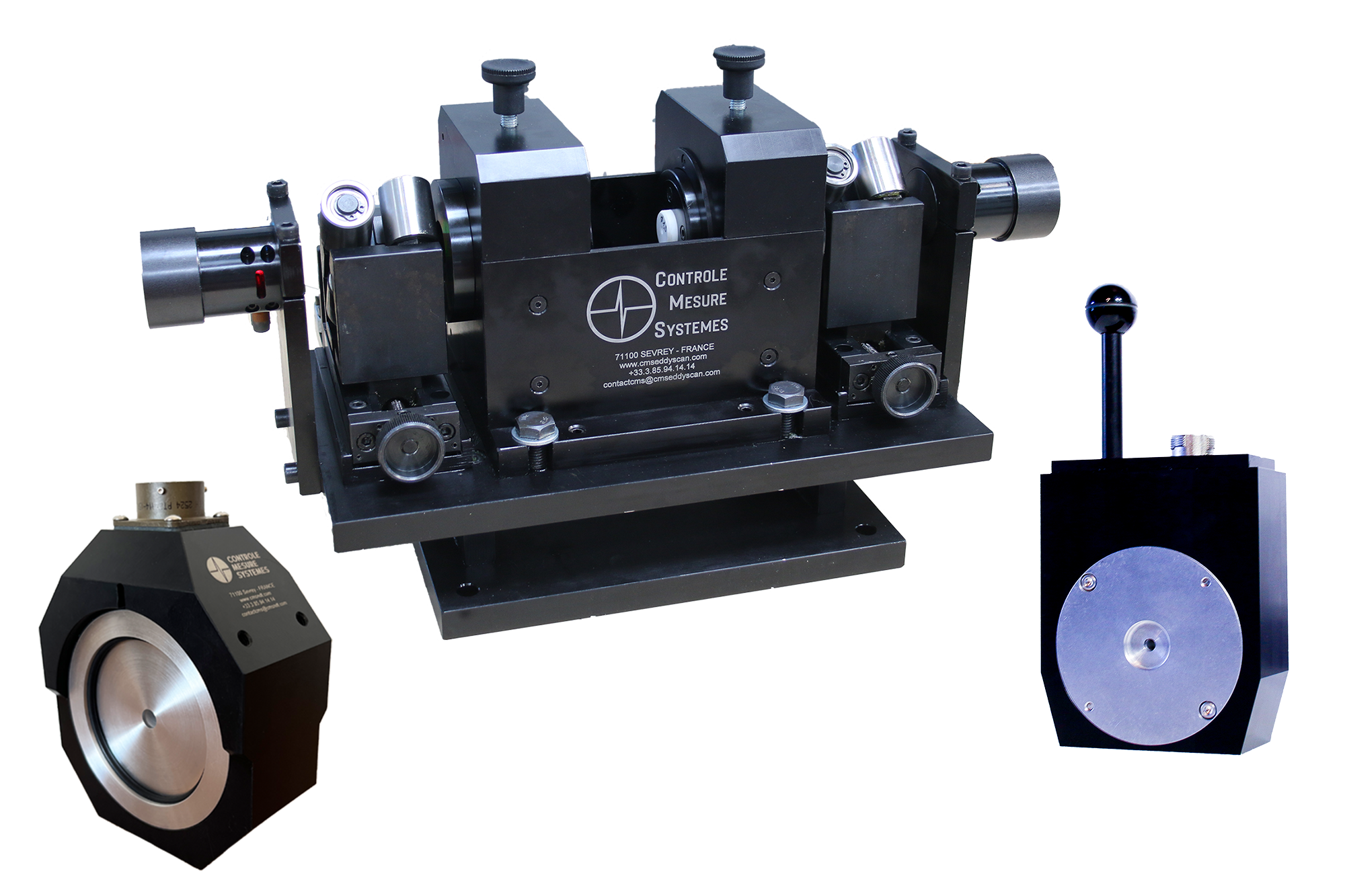

Thanks to CMS systems developed with the latest cutting-edge technologies, it is possible to ensure precise and reliable inspection of all types of wires, whether ferromagnetic or non-magnetic with very small diameters from 0.1 mm, using Eddy Current and Ultrasonic technologies. These inspections ensure their compliance with industrial standards and their reliability in service.

Installed on-line or off-line, our specially designed systems can detect a wide range of defects arising during the various manufacturing processes:

Our membership of the IWCEA community makes us the French experts in the wire and cable sector.

In collaboration with more than 80 German, Austrian and French companies, we share our experience and develop our contacts at wire and cable industry meetings and events abroad and at home.

All our Eddy Current and Ultrasonic systems meet the requirements of current European and international standards (ASTM, API, DIN, SEP, BS, ISO, ASME, ASNT…), calibration standards and comply with NF EN ISO 15548-1, NF EN ISO 15548-2, NF EN ISO 15548-3, NF EN ISO 22232-1.

Discover our exemples of NDT inspections already carried out on wire:

Short and transverse defects detection of non-magnetic wire thanks to Eddy Current encircling coil (copper and aluminum wire)

Short and transverse defects detection of magnetic wire thanks to Eddy Current magnetizing unit

Longitudinal defects detection thanks to Eddy Current rotating head RotoETscan TRVC

Longitudinal defects detection of any orientation thanks to Ultrasonic rotating head RotoUTscan

Hot wire testing with specific Eddy Current encircling coil

Combined Eddy Current and Ultrasonic testing for complete product inspection

Since 1988, CMS designs manufactures and installs Non-Destructive Testing systems for wires & cables inspection

Start with an Eddy Current/Ultrasonic product and build a 100% customized solution based on our experience and to meet your specific needs

Production and design of all Eddy Current & Ultrasonic probes, sensors and software on our own premises (mechanical and electronic design office, engineering, etc.)

Highly responsive in providing assistance and information to our customers

A wide range of complementary Eddy Current/Ultrasonic systems/accessories that can be combined for wire & cable inspection

Eddy Current and Ultrasonic inspection results are displayed in real time and traceabilit is ensured

Inspection speed optimized to production constraints

Partner of IWCEA, which promotes us as a French expert in the wire and cable sector

INNOVATION: Ability to combine Eddy Current and Ultrasonic inspection methods for 100% product inspection

Contact details Fr

CONTROLE MESURE SYSTEMES

6 rue des Loches

71100 Sevrey – France

Contact details USA

CONTROLE MESURE SYSTEMES INC.

175 Pearl Street

Brooklyn, NY 11201 – USA

This new workspace, costing around 2.2 million euros, will enable CONTROLE MESURE SYSTEMES to increase its production capacity, develop its business by conquering new markets, and thus reinforce its position as leader in the NON-DESTRUCTIVE CONTROLE sector.

FEDER contribution : 590,000 Euros

For further information : https://www.europe-bfc.eu

Ce nouvel espace de travail, représentant un coût d’environ 2.2 millions d’euros, permettra à CONTROLE MESURE SYSTEMES d’accroitre sa capacité de production, de développer son activité par la conquête de nouveaux marchés et ainsi renforcer sa place de leader sur le secteur du CONTROLE NON DESTRUCTIF.

Montant FEDER : 590 000 Euros

Pour en savoir + : https://www.europe-bfc.eu