Home | Next-Level NDT by CMS: Precision Eddy Current System for Steel Bars Inspection

Home | Next-Level NDT by CMS: Precision Eddy Current System for Steel Bars Inspection

When it comes to non-destructive testing of steel bars, precision and reliability are paramount.

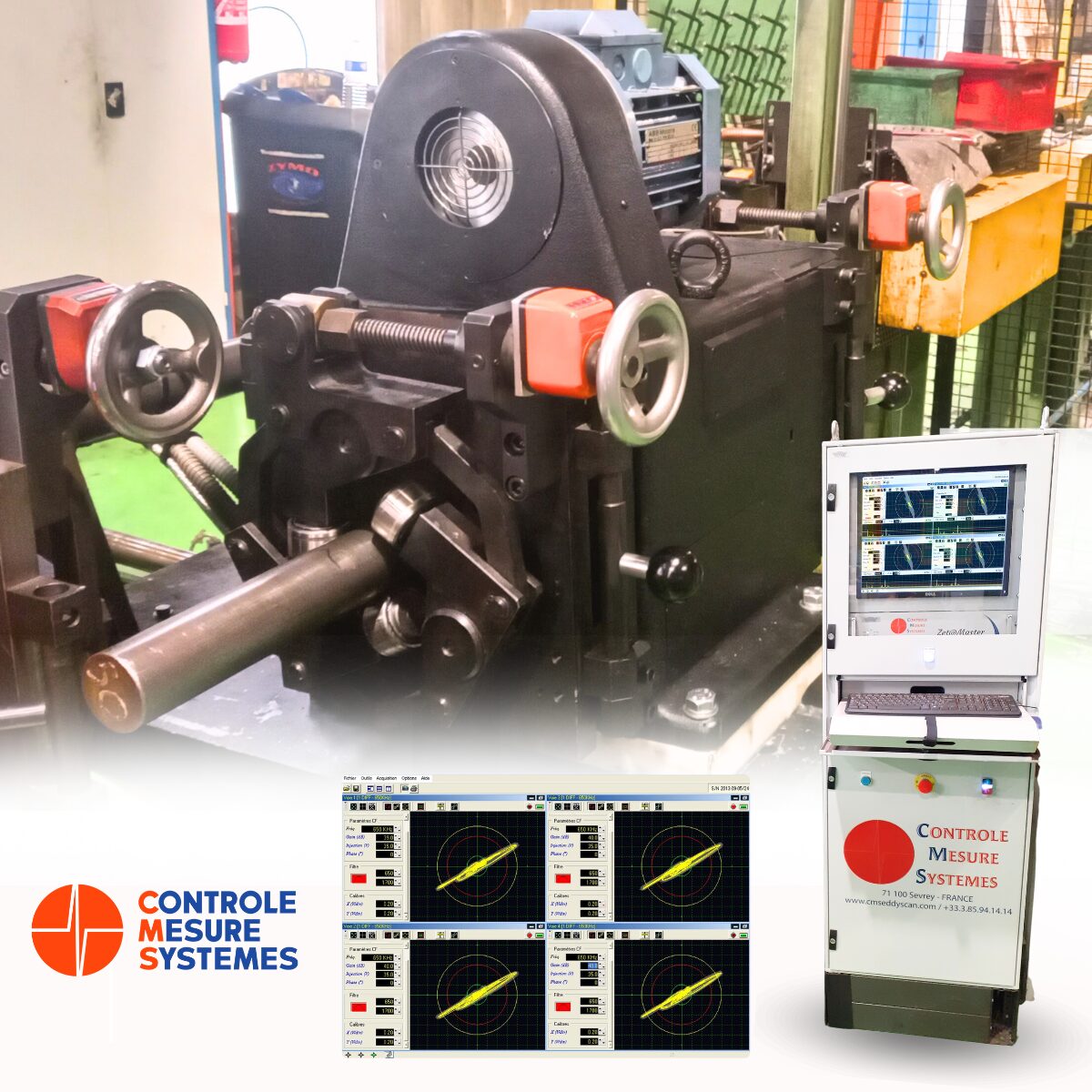

Our latest Eddy Current rotating head installation ensures highly accurate and dependable inspection of round bars with a diameter range of up to 60 mm, detecting even the smallest surface defects. Thanks to this system, our customer will improve the performance and efficiency of its production line.

𝗛𝗼𝘄 𝗜𝘁 𝗪𝗼𝗿𝗸𝘀:

The bar moves in translation through the rotating head, where two or four Eddy Current probes are turning around it to detect surface/sub-surface longitudinal defects. The inspection is carried out with an helical pitch. Combined with the high-performance Eddy Current Zet@Master instrument, results are displayed in real-time as a timebase or Lissajous figure, and a comprehensive inspection report is generated for full traceability.

𝗞𝗲𝘆 𝗙𝗲𝗮𝘁𝘂𝗿𝗲𝘀 𝗼𝗳 𝗢𝘂𝗿 𝗥𝗼𝘁𝗼𝗘𝗧𝘀𝗰𝗮𝗻:

✅ High-speed inspection: up to 6 m/s

✅ Contactless signal transmission

✅ Clearance compensation (GAP)

✅ Ultra-fast adjustment time

✅ Robust monobloc construction, with a solid centering device on each side of the head

✅ Detection of defects as small as 30µm

✅ Contactless inspection

✅ Bearing temperature sensors

✅ Available with 2 or 4 channels

✅ Available options with centrifugal rotation plate, fix rotation plate or adjustable rotation plate

💬 Ready to take your NDT process to the next level ? Contact us to learn more: contactcms@cmsndt.com

www.cmsndt.com

Contact details Fr

CONTROLE MESURE SYSTEMES

6 rue des Loches

71100 Sevrey – France

Contact details USA

CONTROLE MESURE SYSTEMES INC.

175 Pearl Street

Brooklyn, NY 11201 – USA

This new workspace, costing around 2.2 million euros, will enable CONTROLE MESURE SYSTEMES to increase its production capacity, develop its business by conquering new markets, and thus reinforce its position as leader in the NON-DESTRUCTIVE CONTROLE sector.

FEDER contribution : 590,000 Euros

For further information : https://www.europe-bfc.eu

Ce nouvel espace de travail, représentant un coût d’environ 2.2 millions d’euros, permettra à CONTROLE MESURE SYSTEMES d’accroitre sa capacité de production, de développer son activité par la conquête de nouveaux marchés et ainsi renforcer sa place de leader sur le secteur du CONTROLE NON DESTRUCTIF.

Montant FEDER : 590 000 Euros

Pour en savoir + : https://www.europe-bfc.eu