Home | Innovative Ultrasonic Thickness Measurement: A Comprehensive Inspection Solution for Tubes

Home | Innovative Ultrasonic Thickness Measurement: A Comprehensive Inspection Solution for Tubes

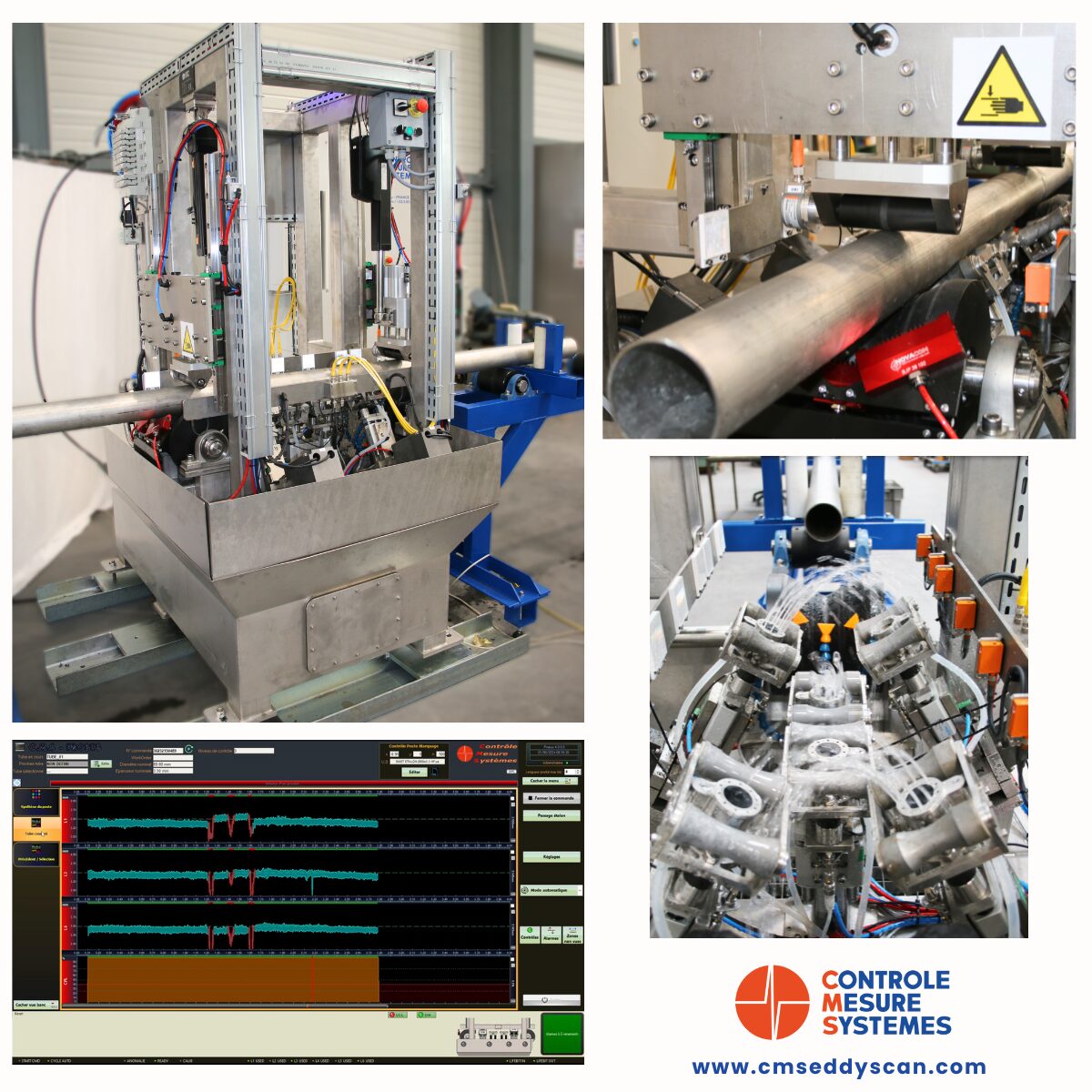

We are pleased to announce the successful installation of our Ultrasonic testing station for thickness measurement ! ✅

This project involved innovative mechanical and electronic developments to deliver a precise and turnkey inspection solution tailored to our customer’s needs. 💡

This system detects localized variations in the inner wall thickness of seamless steel tubes (with diameters ranging from 80 to 280 mm), enabling the identification of natural defects such as “pull-outs.”

Key features of this outstanding project include :

✔ 𝗙𝘂𝗹𝗹𝘆 𝗰𝘂𝘀𝘁𝗼𝗺𝗶𝘇𝗲𝗱 𝘀𝘆𝘀𝘁𝗲𝗺: Tailored to meet the specific needs and constraints of our customer

✔𝗛𝗶𝗴𝗵 𝗶𝗻𝘀𝗽𝗲𝗰𝘁𝗶𝗼𝗻 𝘀𝗽𝗲𝗲𝗱: Capable of up to 1 m/s, boosting productivity

✔𝗢𝗽𝘁𝗶𝗺𝗮𝗹 𝗮𝗻𝗱 𝗽𝗿𝗲𝗰𝗶𝘀𝗲 𝗿𝗲𝘀𝘂𝗹𝘁𝘀: Equipped with a 6 Ultrasonic transducers to cover the full product range. Each inspection utilizes 3 probes to measure along 3 generatrices of the tube.

✔𝗔𝗱𝗮𝗽𝘁𝗮𝗯𝗶𝗹𝗶𝘁𝘆: The system accommodates various tube thicknesses and dimensions (thicknesses from 2.70 to 50 mm / lengths from 3 to 15m)

✔𝗔𝗱𝘃𝗮𝗻𝗰𝗲𝗱 𝗖𝗠𝗦 𝗠𝘂𝗹𝘁𝗶𝗨𝗧𝘀𝗰𝗮𝗻 𝗨𝗹𝘁𝗿𝗮𝘀𝗼𝗻𝗶𝗰 𝗴𝗲𝗻𝗲𝗿𝗮𝘁𝗼𝗿 𝗮𝗻𝗱 𝘀𝗼𝗳𝘁𝘄𝗮𝗿𝗲: Provides real-time display of inspection results and generates comprehensive, detailed inspection reports

At CMS, quality and performance are at the heart of everything we do. We meticulously analyze each of our customers’ inspection requirements to deliver systems tailored to their specific objectives.

Your products deserve top-tier inspection – Elevate your performance with CMS systems.

Contact us : contactcms@cmsndt.com 📧

www.cmsndt.com

Contact details Fr

CONTROLE MESURE SYSTEMES

6 rue des Loches

71100 Sevrey – France

Contact details USA

CONTROLE MESURE SYSTEMES INC.

175 Pearl Street

Brooklyn, NY 11201 – USA

This new workspace, costing around 2.2 million euros, will enable CONTROLE MESURE SYSTEMES to increase its production capacity, develop its business by conquering new markets, and thus reinforce its position as leader in the NON-DESTRUCTIVE CONTROLE sector.

FEDER contribution : 590,000 Euros

For further information : https://www.europe-bfc.eu

Ce nouvel espace de travail, représentant un coût d’environ 2.2 millions d’euros, permettra à CONTROLE MESURE SYSTEMES d’accroitre sa capacité de production, de développer son activité par la conquête de nouveaux marchés et ainsi renforcer sa place de leader sur le secteur du CONTROLE NON DESTRUCTIF.

Montant FEDER : 590 000 Euros

Pour en savoir + : https://www.europe-bfc.eu