Home | CONTROLE MESURE SYSTEMES offers dedicated instruments for inspection of wires and small diameters parts

Home | CONTROLE MESURE SYSTEMES offers dedicated instruments for inspection of wires and small diameters parts

CONTROLE MESURE SYSTEMES is a French company that has been designing and manufacturing Non-Destructive Testing systems for almost 35 years. Specializing in Eddy Current and Ultrasonic testing, the company combines these 2 complementary methods in combined test benches.

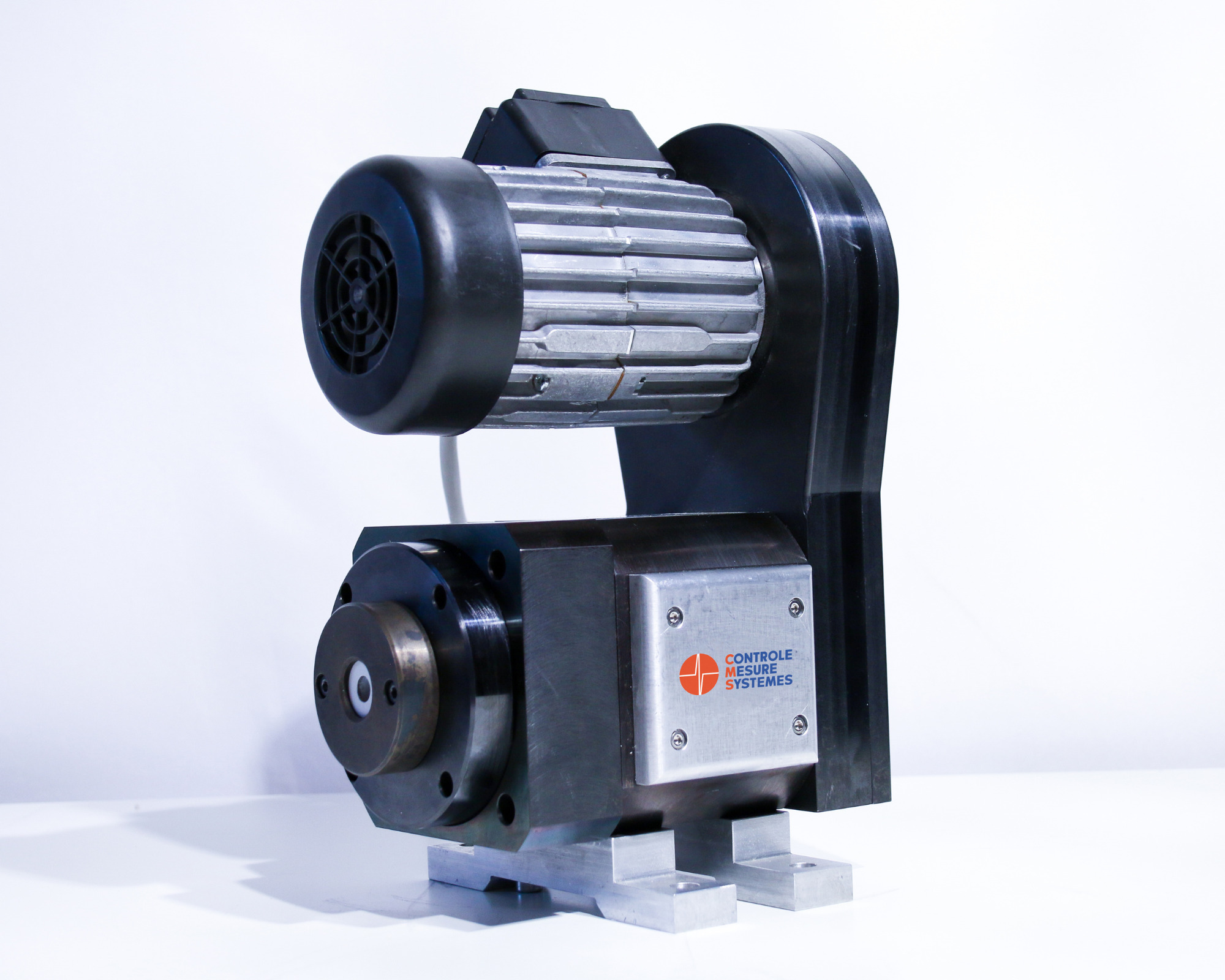

The company’s aim is to provide an inspection solution for every customer need, and has designed an Eddy Current rotating head: RotoETscan TRVC, dedicated to the inspection of wire and small-diameter parts (Ø 0.8 to 10 mm range).

This system is easily integrated into an inspection line, with a cassette adapted to the product diameter. Eddy current probes installed inside the cassette rotate at high speed around the product (up to 18,000 rpm). This model can detect longitudinal defects on wire, bar or single parts at very high inspection speeds (up to 3m/s).

For inspection of wire or continuous products, CONTROLE MESURE SYSTEMES also designs opening eddy-current probes that can be inserted directly into production without having to cut or stop it. These probes are ideal for continuous monitoring of butt-welded wire coils. Defects detected are spot and cross defects.

CONTROLE MESURE SYSTEMES is constantly innovating to offer its customers effective solutions tailored to their needs.

Contact details Fr

CONTROLE MESURE SYSTEMES

6 rue des Loches

71100 Sevrey – France

Contact details USA

CONTROLE MESURE SYSTEMES INC.

175 Pearl Street

Brooklyn, NY 11201 – USA

This new workspace, costing around 2.2 million euros, will enable CONTROLE MESURE SYSTEMES to increase its production capacity, develop its business by conquering new markets, and thus reinforce its position as leader in the NON-DESTRUCTIVE CONTROLE sector.

FEDER contribution : 590,000 Euros

For further information : https://www.europe-bfc.eu

Ce nouvel espace de travail, représentant un coût d’environ 2.2 millions d’euros, permettra à CONTROLE MESURE SYSTEMES d’accroitre sa capacité de production, de développer son activité par la conquête de nouveaux marchés et ainsi renforcer sa place de leader sur le secteur du CONTROLE NON DESTRUCTIF.

Montant FEDER : 590 000 Euros

Pour en savoir + : https://www.europe-bfc.eu