Home | Probus: Intelligent software for Non-Destructive Testing

Home | Probus: Intelligent software for Non-Destructive Testing

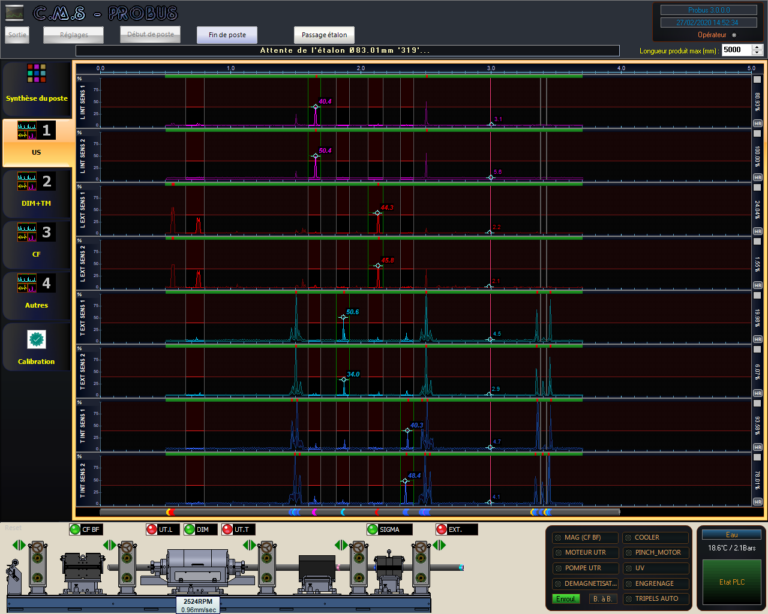

CONTROLE MESURE SYSTEMES has developed a software program called Probus, capable of collecting information sent by NDT equipment. The aim is to provide a good/bad sorting system for the tube being inspected, and to ensure traceability by producing inspection reports by product or batch.

On an inspection system, Probus is the decision-making element:

The software communicates directly with the test bench’s automation system, acting as its Human Machine Interface.

Inspection reports can be presented to quality departments as proof of control, and can include a list of detected faults and their positions.

Alarm thresholds can be set in software for each channel. When a signal crosses the alarm threshold, it is indicated on the display and the product is considered faulty.

The supervision software can handle several types of signal:

This software can be combined with a wide range of systems of all makes, such as ultrasonic rotating heads, eddy current rotating heads, CF coil holders, magnetizing and demagnetizing units, and many others.

Because Probus is capable of collecting all analog signals, CONTROLE MESURE SYSTEMES can easily integrate the software on an obsolete bench and revamp the installation.

Contact details Fr

CONTROLE MESURE SYSTEMES

6 rue des Loches

71100 Sevrey – France

Contact details USA

CONTROLE MESURE SYSTEMES INC.

175 Pearl Street

Brooklyn, NY 11201 – USA

This new workspace, costing around 2.2 million euros, will enable CONTROLE MESURE SYSTEMES to increase its production capacity, develop its business by conquering new markets, and thus reinforce its position as leader in the NON-DESTRUCTIVE CONTROLE sector.

FEDER contribution : 590,000 Euros

For further information : https://www.europe-bfc.eu

Ce nouvel espace de travail, représentant un coût d’environ 2.2 millions d’euros, permettra à CONTROLE MESURE SYSTEMES d’accroitre sa capacité de production, de développer son activité par la conquête de nouveaux marchés et ainsi renforcer sa place de leader sur le secteur du CONTROLE NON DESTRUCTIF.

Montant FEDER : 590 000 Euros

Pour en savoir + : https://www.europe-bfc.eu